Increasing Marketable Potato Yield and Internal Quality

It takes countless hours of research and continuous trial work to get the right potato nutrition regimen in place. Growers want proof. And growers want to trust in the process.

A well-designed nutrition program — one that uses the right nutrients at the right time in the right form and in the right mix — results in higher marketable yields, better storage qualities, improved specific gravities and a lower risk of disease.

The nutrients used in Agro-K’s science-driven potato program do just that, as potato grower Traye Radach have learned over the years.

“Agro-K’s program is like NPK (nitrogen, phosphorus and potassium) to us; we can’t grow potatoes without it,” said potato grower Traye Radach. “We’ve always had good results, so we’ve had no reason to change.”

“Overall, the yield and quality of our spuds has been very good for a long period of time.

”Radach and his father, Jerry, farm a little over 600 acres in Moses Lake, Washington. Traye’s been working at Radach Farms since graduating college 20-some years ago and the duo has, for many years, turned to Agro-K for help.

Why? Because premium potato quality and increased yields are essential to their farm’s success. Agro-K’s science-driven approach encourages both.

Jeff Oertwych, a Simplot crop adviser in Umatilla, Oregon, said Agro-K’s approach is something his growers have grown to appreciate.

“When you can show them Agro-K’s results from many different crops, it’s hard for growers to say that the program doesn’t work,” Oertwych said.

His growers provided feedback similar to Radach’s. They’ve witnessed “massive” roots and root hairs, increased plant health, better disease resistance, higher yields, better quality and increased specific gravities.

They’ve also experienced a greater resistance to heat stress, a problem haunting potato growers across many areas of the country.

“We get hot summer weather (temperatures well above 100°) here in eastern Oregon,” Oertwych said. “But growers using Agro-K’s program say their plants seem to take the heat stress and shock better.”

“We seem to make it through the summer months with minimal damage.”

The health of the potato tuber is key and Agro-K’s program helps mitigate and reduce a variety of stressors.

“Any time you can produce a healthier plant, you’re going to see bigger tubers and a better quality crop,” Oertwych said. “I’ve seen the results and so have my growers.”

“We aren’t going to waiver from Agro-K’s plan much, that’s for darn sure.”

What’s the plan? It all starts with increasing tuber calcium.

Strong calcium levels in the roots, the foundation of the potato plant, are essential. Growers should apply two applications of the appropriate rate of foliar, non-potassium phosphite during hooking or tuber initiation. There must be adequate levels of soil calcium in the tuber root zone to be pulled into the tuber to ensure high specific gravities and internal quality.

Strong calcium levels in the roots, the foundation of the potato plant, are essential. Growers should apply two applications of the appropriate rate of foliar, non-potassium phosphite during hooking or tuber initiation. There must be adequate levels of soil calcium in the tuber root zone to be pulled into the tuber to ensure high specific gravities and internal quality.

“When you understand how a nutrient gets into and is used in the plant, you know when and how to apply it,” said Ken Dart, national technical manager at Agro-K. “Our products and crop programs are strictly based on the science of plant physiology. It’s a science-driven nutritional approach and it’s what makes us unique in the market and makes our results and performance in the field far better and more consistent.”

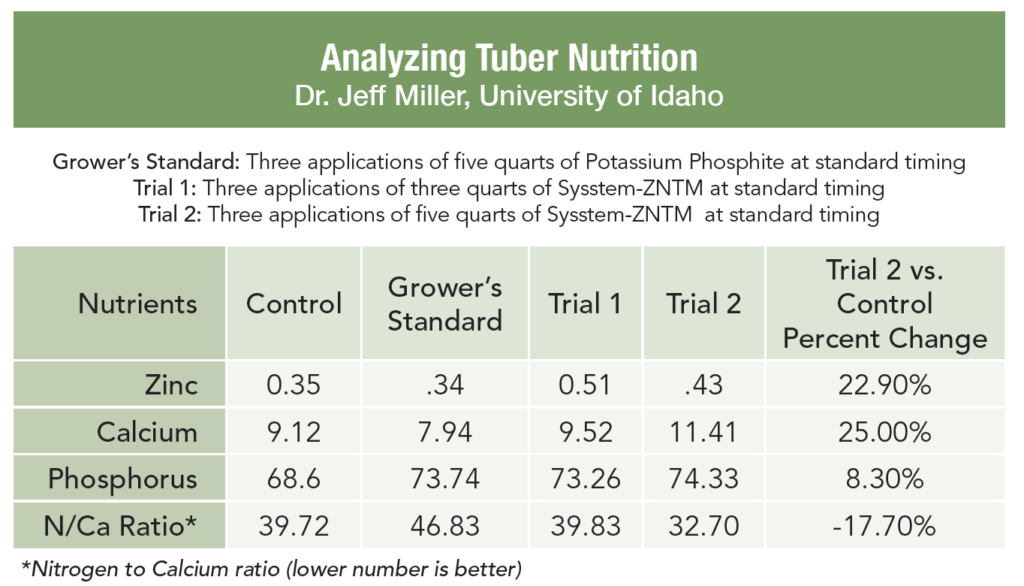

The best, most efficient way to get calcium into the potato tuber is through the tuber root hairs and stolons, and you can’t do that with foliar calcium sprays. Instead, calcium must be pulled into the tubers directly with the help of a phosphite-driven root flush. The Sysstem-Ready® (Zinc Phosphite + Manganese Phosphite) root flush is known to out-perform and pull in more calcium than standard potassium phosphite products (see chart above).

Increased levels of calcium in the tuber lead to larger tuber weights, better cellular structure and internal quality and improved nutritional makeup, resulting in a greater return on the fertilizer investment. They also reduce the risk of foliar and tuber diseases.

And remember, foliar potassium (in any form) applied during tuber cell division will antagonize calcium, hindering calcium uptake into the tuber causing weaker cell walls, reduced internal quality and reduced storage quality. This reduction of tuber calcium in early tuber growth can also lead to greater risk of internal defects, lower weights, specific gravities and increased disease potential.“Bottom line, growers are going to get a healthier plant, a better quality crop and a better yielding crop that will result in more money in their pockets,” said Dave Bloxham, northern rocky mountain sales consultant at Agro-K. “When I work with crop advisers, I tell them that it’s going to take some money to follow the program, but who wouldn’t want to make a prudent investment like this if it’s going to consistently and significantly increase marketable yields and ROI?”

Oertwych and Radach echoed Bloxham’s thoughts. “When you have a return that’s consistently evident, the cost is irrelevant,” Oertwych said. “When you do trials and have bigger yields with better quality, you know the program will pay for itself in a hurry.”

“Sure, there are parts of the program that are expensive,” Radach said. “But if you look at what you can gain in the end, it’s worth it. It has taken our spuds to the next level.”“I trust Agro-K and I trust their program,” he continued. “They provide a lot of good information and research to back up their claims and programs.”